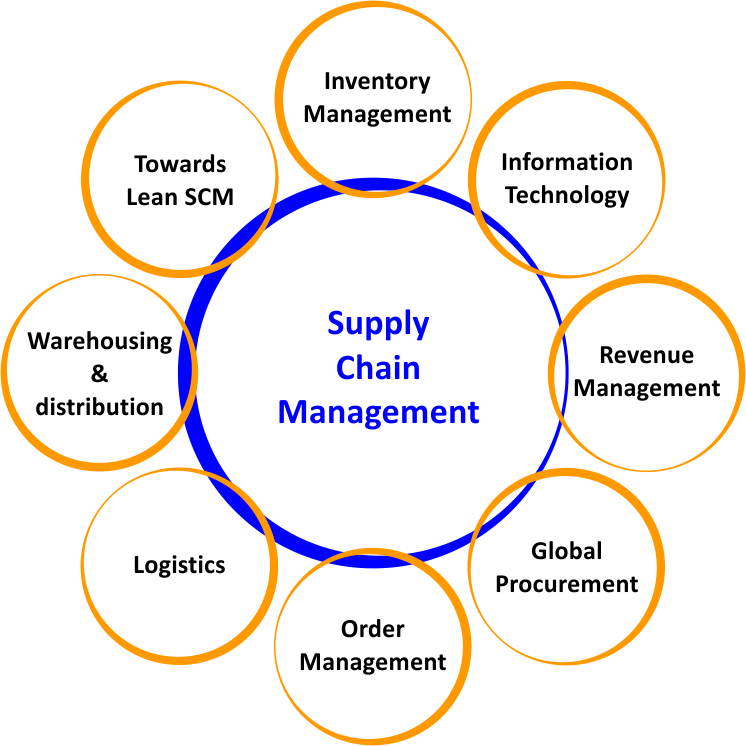

Supply chain is the heart of a business. The supply chain managers often look for various ways to develop customer centric, cost effective supply chain models for better functioning of their business.

During the recession period of 2007-2009, only the companies that used best supply chain strategies survived and others crashed under pressure of on-going changes. You can learn a lot from the strategies of companies which survived and improve your supply chain management in current economy.

- Change is the key to success

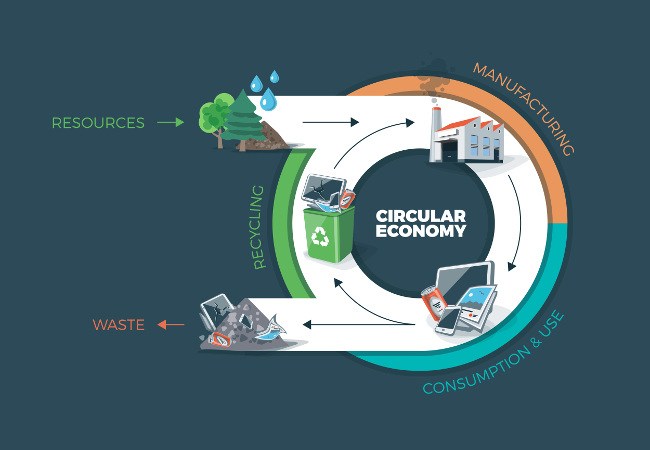

When time changes and things get tough, only people who are adaptable can survive. Always remember to keep your supply chain operations up to date including the latest technologies. When you are moving from one strategy to other, it can cost you a bucket of cash. Therefore, it is always good to consider market risk and go for a design that is going to survive for quite some time.

- Do a SWOT analysis

One of the best supply chain strategies is doing a SWOT analysis. Once you know about your weakness, you can improve them. The weakness will lead to regularly make changes that are needed, which is indeed the most crucial aspect of staying in profitable business.

- Align your SCM according to your business

All companies need not built an inventory. Apart from increasing the cost of storage, inventory also increased overall cost since depreciation also comes into play. For such a case, you can align your SCM to have just-in-time availability of resources. Same is the case with product delivery.

- Optimize product design

Not only the supply chain but you can bring about changes in your product design to increase your profits. For example- instead of round boxes you can go ahead with rectangular ones which occupy less space, thus saving transportation cost. Going for RM suppliers near you is also one of the ways you can stay ahead in the market.

- Manage information, people and process

The key to well-maintained agile supply chain operations is the interaction between various parts including people and process. Always go ahead with a pro-active approach and manage information, people and process in a better way. The clear collaboration of end-to-end supply chain operations, and demand driven insights give outcomes which are cost friendly.

Conclusion

To stay ahead of time, you need to stand out in the crowd. If you are also looking for such opportunities but are confused how to go about it, these strategies are definitely going to help you. Make a plan including different strategies and see what works the best for you.